|

Selected

photos from:

Douglas

DC-3

Re-engine STC Project

In

this project, Pratt and Whitney PT6-67R turbo-prop engines were installed

in a Douglas DC-3, requiring a 40 inch fuselage stretch to maintain

proper CG. Alligator was responsible for all aspects of test equipment

installation and data acquisition for the program (80+ channel digital

low to- moderate-speed and 10 channel high-speed analog/digital hybrid

data acquisition systems). (October 1988 through February 1990)

Mounting flight test

boom on wingtip of DC-3 to measure pitot

pressure, static pressure, angle of attack and angle of side-slip

Modifying airframe

to receive Pratt & Whitney PT6-67R turbo-prop engines

Mounting 5-bladed

propeller

Fitting new rear

cowl section

Aircraft ready for

test flights

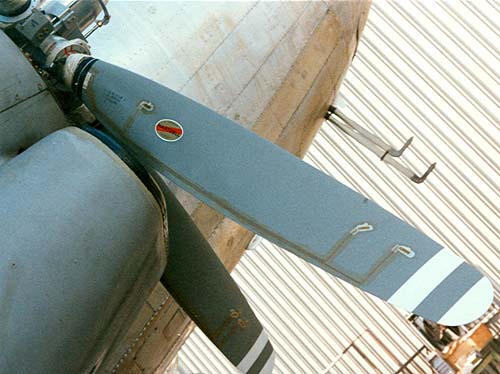

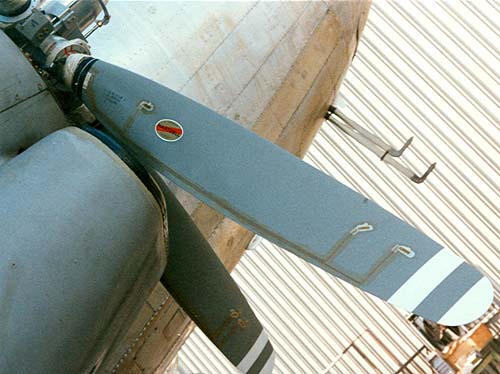

Strain gauges mounted

on propeller for vibration survey tests

Close-up of strain

gauges

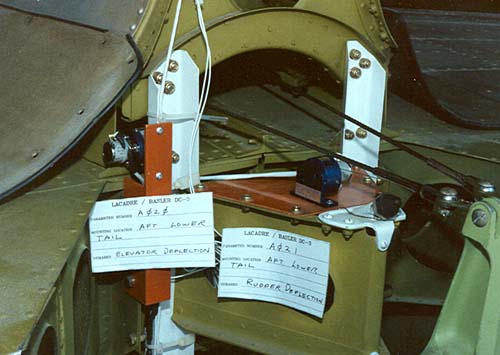

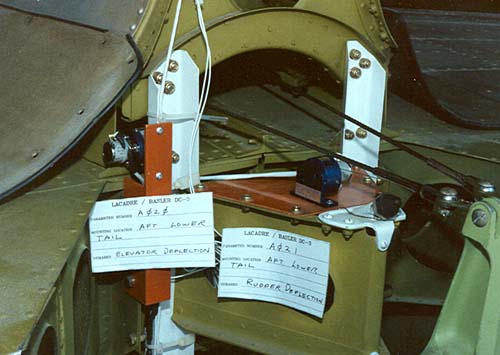

String potentiometers

for measuring elevator position and rudder position

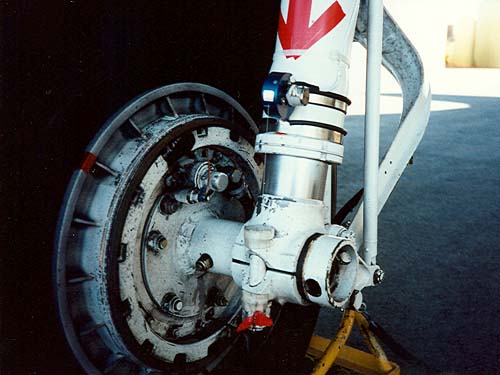

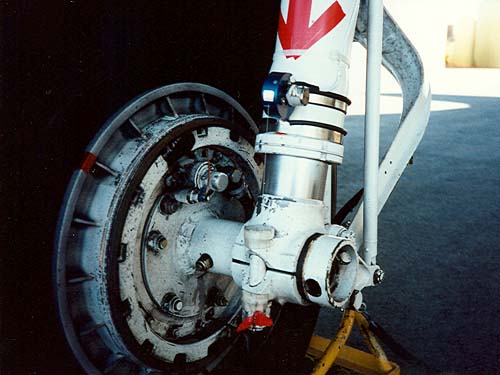

String pot for main

gear strut deflection measurement

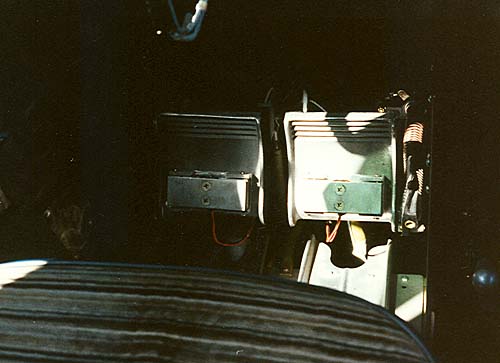

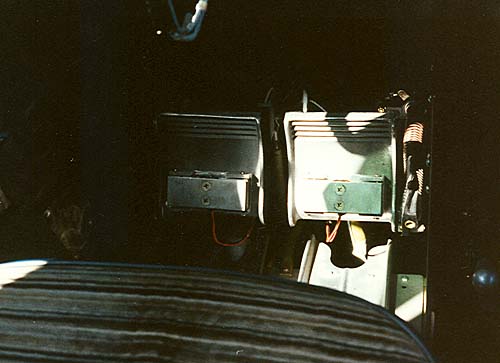

Alligator-designed

and fabricated load cells for measuring pilot rudder forces

Data acquisition

system developed by Alligator for LaCadre flight test department

Basler turbo-prop

DC-3 climbing out on first flight test

Camera theodolite

system used for measuring take-off and landing distances.

Computer recorded data used and coordinated with airborne data system.

Back

to Completed Projects

|